Material MDF Acoustic Panel MDF 3D Wall Panels

We are working toward the company goals of professionalism, modernization, and internationalization. Our firm will make every effort to grow the solid wood acoustic diffuser, movable soundproof walls, and acoustic diffuser absorber industry through rigorous management, sophisticated technology, consistent quality, and attentive service. We will continue to meet our clients’ needs through our true reputation, innovative technology, consistent quality, and good service. We place a high priority on environmental, health, and safety (EHS) performance, ranking it alongside customer happiness, product quality, and production costs, because great EHS performance can help us achieve an advantage in a highly competitive market.We have now created a tight and comprehensive quality control system, ensuring that each product meets the quality criteria of our customers. Customers from a variety of countries and areas prefer our items.

Introduction

Groove acoustic panels are a type of sound-absorbing panel having grooves on the surface and holes in the back. The back is wrapped in black felt to protect the internal acoustic foam from exposure. The groove acoustic panel patterns can be customized, and different patterns can be chosen to satisfy the requirements based on interior design and acoustic effects. The panel offers the acoustic layout and enables for maximum sound quality.The grooved acoustic panels can be used in auditoriums, conference rooms, multi-purpose halls, airports, and other settings.

Function

Direct sound has a constant frequency and pitch since it does not interact with the room. Generally, we try to maintain as much direct sound as possible. Because diffracted sound causes each new reflection from a different direction to somewhat alter the original sound, it is often attempted to eradicate it. Of course, the required diffraction sound can be kept to create a pleasing reverberation while selectively preserving the purity of the direct sound. Sound absorption is the most prevalent type of acoustic treatment.

Features

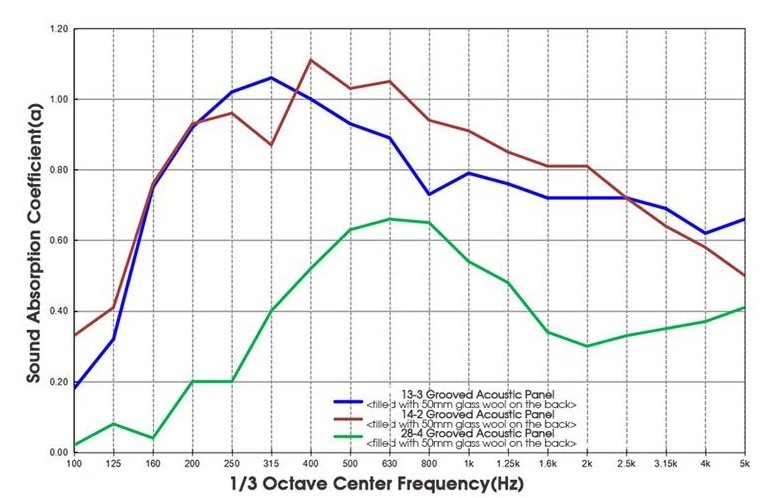

The technology industry uses a variety of materials based on the acoustic concept and reasonable coordination. The acoustics panel has excellent noise reduction and sound absorption ability, particularly for medium and high frequency sound absorption effects.

Simple to install — standardized module design with slots and keel construction. It is simple to setup and quick.

Industrial manufacturing entails using automatic computer control equipment rather than the traditional large-scale manufacture of building materials. The equipment is suitable for large-scale standardized production, which is intended to increase production capacity while simultaneously ensuring product quality.

FAQ

Q: How do you ensure the quality of the goods?

A: We use a comprehensive quality management system throughout the entire process. We will carefully screen upstream suppliers to assure the quality of the basic materials used in groove acoustic panels. Production technologies and employee training receive more emphasis during the manufacturing process. We use innovative equipment and technology to reduce the failure rate of each product to less than 1%, saving money on the manufacturing line. When the product is ready, it is delivered to the packaging workshop. Before shipping, make sure that each board is packed with foam to prevent friction and damage during transport.

Q: Does the melamine acoustic panel have a CE certification?

A: Yes. Our products are distributed all over the world, therefore the CE certificate is required. All of our items have this certificate.

Q: What’s the difference between a standard panel and a melamine acoustic panel?

A: Acoustic panels, also known as soundproof panels, are designed in accordance with soundproofing laws. Acoustic panels provide three basic tasks. Sound absorbing, diffusing, and insulation in relation to a specific sound source and receptor include increasing the distance between the source and receiver, using acoustic panels to reflect or absorb sound wave energy, using damping structures such as melamine acoustic panels, and using active antinoise sound generators.

We always strive for the most sophisticated technology and the highest quality in order to give consumers with the best Material MDF Acoustic Panel MDF 3D Wall Panels! The enterprise spirit of loyalty, responsibility, diligence, and dedication developed through accumulation and cohesion is our spiritual richness and power source for advancement. We hope that the company’s exceptional employees will have the guts to embrace the mission and contribute more to its reform and development.