Plastic Wood Effect Decking

Foresmate plastic wood effect decking features a comprehensive protective covering that protects outdoor flooring from sun and snow damage. Foresmate’s sturdy composite decking with natural wood grain and 100% toxin-free construction allows you to totally immerse yourself in your patio life.

| Product Name |

Plastic Wood Effect Decking |

| Size(W*T*L) | 139 x 22.5 x 3000 mm; length can be customised (2.2–5.8 metres) |

| Surface Treatment | Normal,Brushed, Embossing |

| Color | 12 Colours. Including Royal Teak, Walnut, Natural IPE,Mirage, Antique,etc. |

| Service Life | 15-30 Years |

| Advantage | Foresmate and generation decking is encased in an ultra-durable full protective shield,which offers protection against stains, scratches, snow, and sun damage. |

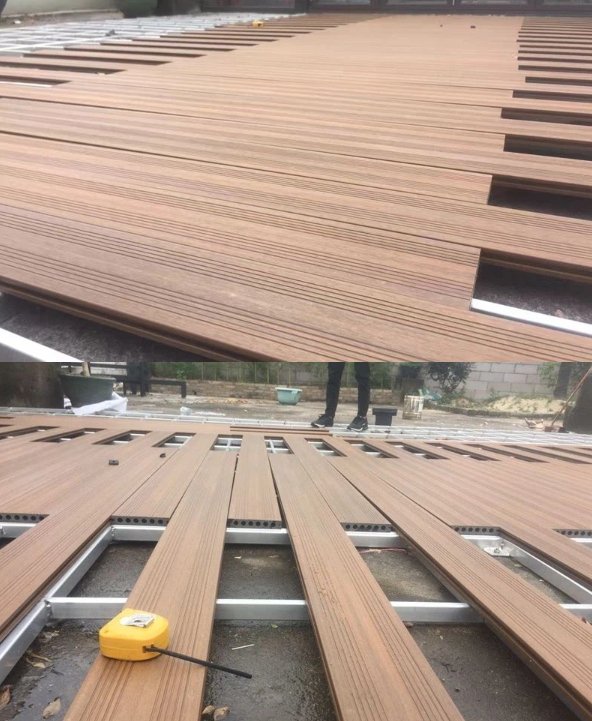

| Application | swimming pool, garden, balcony, backyard, and other outdoor spaces. |

Foresmate plastic wood impression decking is finished with an ultra-durable, complete protective barrier that resists stains, scratches, snow, and sun damage. When youngsters play on the platform, the decking board is anti-slip, safe, and suitable for barefoot use. The low-gloss, realistic wood grain looks and feels like real wood.100% water and rot resistance, with termite protection.There is no need to paint, so maintenance is quite low.

Foresmate plastic composite decking is widely used in hotel, resort, school, hotel, office,hospital, restaurant, garden, villa, and apartment projects.

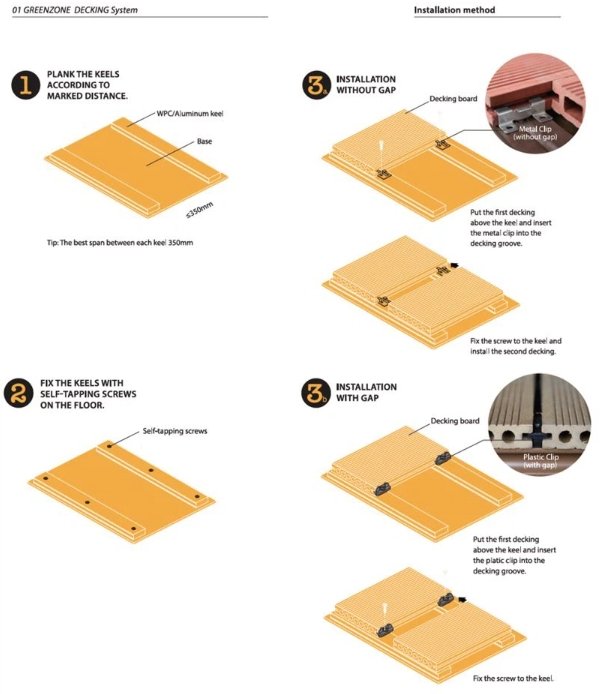

Foresmate Plastic Wood Effect Decking Installation Guide

1) Fix the joist on the floor with a maximum span of 350mm (centre to centre).

2) Attach the first decking to the joist, place the clips into the decking groove, and secure the screws.

3) Install decking boards one by one.

4) Install the fascia board (edge cover).

Quality Control (QC).

1) Colour stability control

To decrease colour variation in bulk productions, we regulate it at the raw material level, mix the raw material and colourant with a calculated percent, ensure the colour sample matches the colour standard, and then rigorously adhere to this colour sample to control the colour.

2) Bulk production control

Raw material purchases and bulk production are tightly monitored to ensure that our goods compete in terms of surface grain, durability, and colour management.