Laminated Decoration PVC Ceilings Panel

Foresmate pvc ceiling has the advantages of antibacterial, heat insulation, noise prevention, etc. It is widely used in hotels, commercial buildings, hospitals, schools, kitchens, etc., and is exported to Southeast Asia, the Middle East, Japan, South Korea, South America and other countries.

|

Brand Name: Foresmate

|

PVC content: 35%-85%

|

|

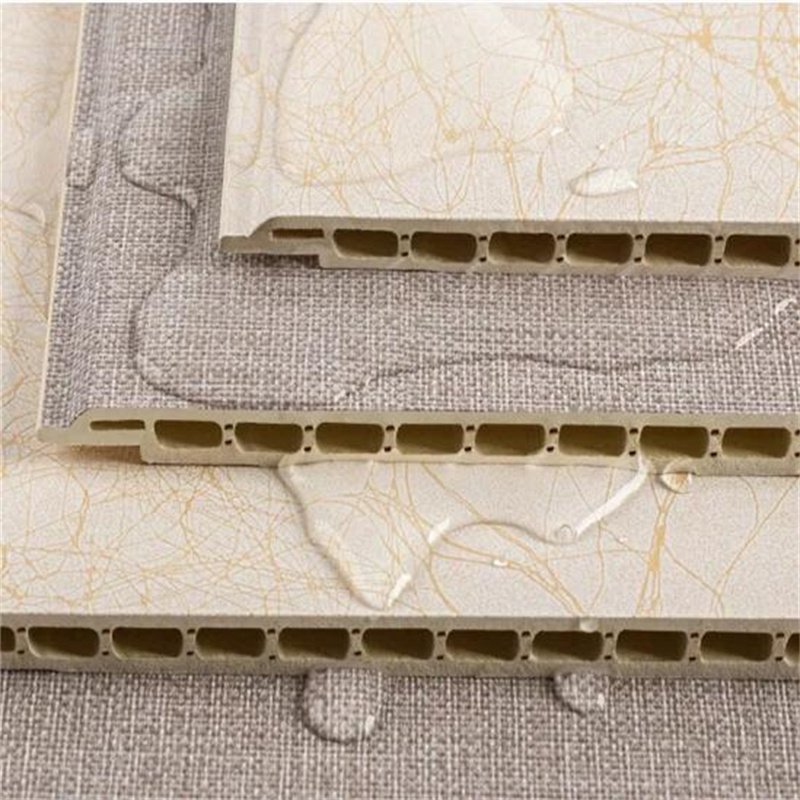

Width:200mm,250mm,300mm,350mm,400mm,595mm,

600mm,605mm

|

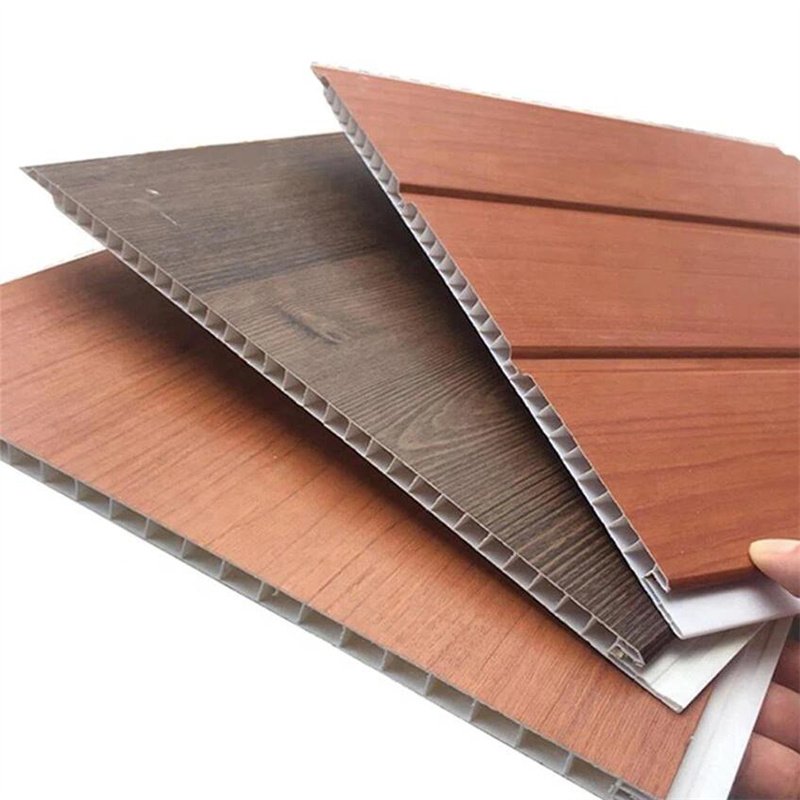

Thickness:5mm,6mm,7mm,7.5mm,8mm,8.5mm,9mm,10mm,12mm

|

|

Length: 5.8m for 20’GP and 5.95m for 40’HQ,or according to your requirement.

|

Surface process: Printing (high glossy or glossy matte ), Hot stamping, Lamination

|

|

Patterns:A large number of designs are available

|

Weight:2.0kg/sqm ~ 5.0kg/sqm

|

|

Material: Polyvinylchloride (PVC), Calcium Carbonate and other additives.

|

Packing:PVC Shrink-film or PE-Film or carton, 10PCS/bale or according to your requirement.

|

|

Features:Light in Weight, Easy Installation, High toughness, Waterproof, High Intensity, Aging Resistance, Easy to clean.

|

|

|

Delivery Detail:15~20 days for 1*40HQ container after receiving down payment.

|

Application:living room,bathroom,kitchen and office’ wall and ceiling decoration.

|

This kind of material has advantage below:

1. Self-fire extinguishing, non-flammable.

2. DIY is all right.

3. It is impenetrable by insects or termites, and won’ t rot or rust.

4. Resistance to weather/ special chemicals; Waterproof / Washable.

5. The excellent rigid and superior impacted surface is without any peeling.

6. Natural wood grain: showing authentic wood structure and artistic sense.

7. Easy to be cut, drilled, nailed, sawed, and riveted.

8. Quick maintenance and no need of painting.

9. The simple and fast installation can save a lot of time and manpower cost.

Foresmate Laminated Decoration PVC Ceilings Panel

Quality Control (QC).

1) Color stability control

To decrease color variation in bulk productions, we regulate it at the raw material level, mix the raw material and colourant with a calculated percent, ensure the color sample matches the color standard, and then rigorously adhere to this color sample to control the color.

2) Bulk production control

Raw material purchases and bulk production are tightly monitored to ensure that our goods compete in terms of surface grain, durability, and color management.