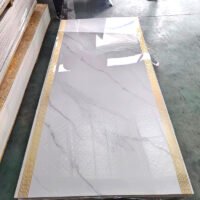

UV PVC Marble Sheet Produced by Linyi City Factory

| Name | UV PVC Marble Sheet |

| Size | 1220*2440mm(length as customer request) |

| Thickness | 2-5.0mm(usually is 3.0mm) |

| Color | Marble grain, Wood grain, Solid color,3D design,Accept customized design |

| Material | PVC + Calcium Carbonate + Other Chemical Additives |

Features

PVC Marble Sheet, a substitute for natural marble,weatherproof and may be utilised in a variety of environments, including decoration. However, if the product is used in water or a humid environment, it must be paired with a waterproof adhesive. If an ordinary glue is employed, it is easy for the adhesive to fail in an environment in which water molecules have been infiltrated for an extended period of time, causing harm.

Fireproof

Because Foresmate PVC Marble Sheet contains a high percentage of PVC raw ingredients, the finished product has PVC-like flame retardancy. In general, fire sources have difficulty igniting the product. Even if the product is ignited by another item, the PVC Marble Sheet will not burn. It can achieve the benefits of flame retardants, reduce fire loss, and protect the home’s walls.

Anti-insect

Foresmate PVC Marble Sheet’s major components are PVC and calcium carbonate, both of which offer anti-insect qualities. Furthermore, because Foresmate PVC Marble Sheet is extruded at a high temperature, the surface is hard and smooth, and common pests such as termites find it difficult to consume, it has good insect resistance.

Anti-enzyme

Foresmate PVC Marble Sheet is formed by melting raw materials such as PVC and calcium carbonate at a high temperature of 200 degrees Celsius. After extrusion moulding, the entire production environment is at high temperatures, allowing no organic stuff to exist. Even if organic matter is connected to the product’s surface, because the surface layer is an airtight UV coating, organic matter such as mildew can be readily removed, restoring the product to its original cleanliness.